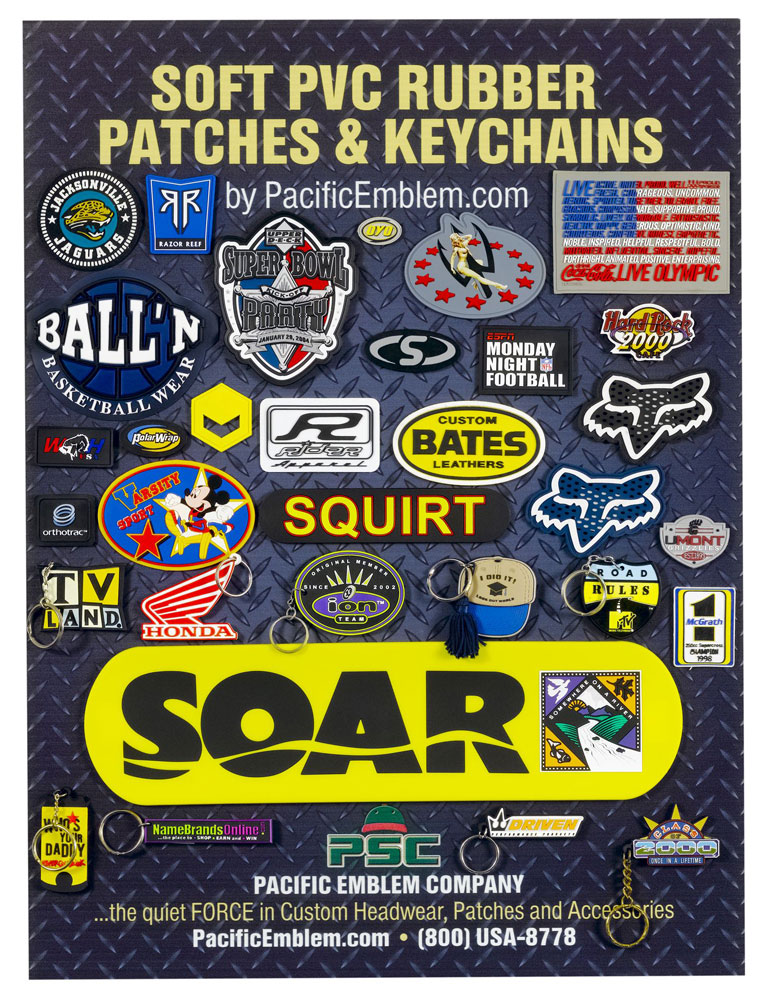

CUSTOM Precision-Cut™ Soft PVC & Rubber Patches

Technical & unique patches that capture your brand

Talented Artisans carefully mold each Precision-Cut Rubber Patch to exact specifications. PMS color matches, Extreme-Cut Shapes and sizes from 1/4” to 17”…Rubber done the right way!

Precision-cut rubber patches have become more and more popular over the past few years and it is our goal to remain the leader in high quality, cutting-edge in rubber and soft PVC patches.

Rubber patches are excellent for caps, jackets, surf shorts, snowboard apparel, neoprene products, backpacks, car mats, and other products where you require the “high tech” look and durable results. We can also mix mediums by combining rubber, mesh, and other substrates, to create the ultimate rubber patch. To get started, request a Quick Quote by filling out the short form on this page. Minimum: 300

Request a Quick Quote!

Introducing Precision-Cut Soft PVC & Rubber Patches – A Durable and Versatile Solution for Your Brand

Welcome to our comprehensive guide on precision-cut soft PVC and rubber patches, a cutting-edge solution that offers exceptional durability and versatility for enhancing your brand. In this article, we will explore the numerous benefits, applications, customization options, and advantages of precision-cut soft PVC and rubber patches over traditional embroidered patches. We will also discuss the manufacturing process involved and provide real-life case studies showcasing successful branding strategies with these innovative patches. Whether you’re in the apparel industry, military, outdoor gear, or any other business seeking a long-lasting and eye-catching branding solution, precision-cut soft PVC and rubber patches could be the answer you’ve been looking for. Read on to discover how these patches can elevate your brand identity to new heights.

The Benefits of Precision-Cut Soft PVC & Rubber Patches

- Enhanced Durability and Versatility

If you’re tired of patches that fray, fade, or fall apart at the first sign of adventure, then precision-cut soft PVC & rubber patches are here to save the day. Made from durable materials, these patches can withstand the test of time, whether you’re scaling mountains or just braving the daily commute. Plus, they’re incredibly versatile, so you can stick them on backpacks, jackets, hats, or whatever else you fancy.

- Long-lasting Brand Recognition

When it comes to building brand recognition, precision-cut soft PVC & rubber patches are like walking billboards for your business. With their eye-catching designs and vibrant colors, these patches ensure that your logo or message stands out in a sea of ordinary. And because they’re built to last, your brand will be front and center for years to come, leaving a lasting impression on anyone who lays eyes on them.

How Precision-Cut Soft PVC & Rubber Patches Enhance Branding

- Eye-Catching Design Options

Say goodbye to boring patches that blend into the background. Precision-cut soft PVC & rubber patches offer a wide range of design options that will make your brand shine. From intricate details to bold and vibrant colors, these patches ensure that your logo or artwork pops and grabs attention, turning heads wherever they go.

- 3D Texture and Dimensionality

Forget about flat and lifeless patches. Precision-cut soft PVC & rubber patches add a whole new level of texture and dimensionality to your branding. With their raised surfaces and unique embossed designs, these patches not only look cool, but they also feel great to the touch. It’s like having a mini work of art right on your favorite jacket or bag.

- Vibrant Colors and High Level of Detail

When it comes to showcasing your brand, color and detail are everything. Precision-cut soft PVC & rubber patches deliver on both fronts. With their ability to reproduce even the tiniest of details and their rich and vibrant colors, these patches ensure that your brand is represented with utmost accuracy and visual impact. Get ready to turn heads and spark conversations wherever you go.

Applications and Uses of Precision-Cut Soft PVC & Rubber Patches

- Apparel and Fashion Industry

Fashion-forward individuals and clothing brands alike can take advantage of precision-cut soft PVC & rubber patches. Whether you want to add a dash of personality to your favorite denim jacket or give your clothing line a unique and memorable touch, these patches are a stylish choice that will make your brand stand out in the fashion crowd.

- Military and Law Enforcement

From military uniforms to police gear, precision-cut soft PVC & rubber patches offer a durable and tactical solution for those in the line of duty. These patches can be easily attached to uniforms, bags, or equipment, making them an essential accessory for anyone serving in the armed forces or law enforcement.

- Outdoor Gear and Adventure Brands

For outdoor enthusiasts and adventure brands, precision-cut soft PVC & rubber patches are a match made in heaven. Whether you’re scaling mountains, trekking through forests, or paddling down raging rivers, these patches can withstand the rigors of any adventure. Stick them on your camping gear, backpacks, or hats, and let everyone know that you’re ready to embrace the great outdoors in style.

The Manufacturing Process of Precision-Cut Soft PVC & Rubber Patches

- Design and Artwork Creation

It all begins with a spark of creativity. Design and artwork creation are the first steps in bringing your precision-cut soft PVC & rubber patches to life. Whether you have a logo in mind or need help from a talented designer, this stage is all about turning your ideas into a visual masterpiece that will proudly represent your brand.

- Mold Making and Pre-Production

Once the design is finalized, it’s time to make the magic happen with mold making and pre-production. Skilled craftsmen create custom molds that will shape the patches into perfection. This crucial step ensures that every detail of your design is accurately replicated, resulting in a high-quality patch that proudly showcases your brand.

- Injection Molding and Finishing

With the molds ready, it’s time for the injection molding process. Soft PVC or rubber materials are injected into the molds, taking the shape of your design. After a curing period, the patches are carefully removed, trimmed, and expertly finished, ready to take their place as the face of your brand. The attention to detail at this stage ensures that every patch meets the highest standard of quality and craftsmanship.

Now that you’re armed with the knowledge of precision-cut soft PVC & rubber patches, it’s time to make your brand stand out in a durable and versatile way. Whether you want to enhance branding, showcase your style, or gear up for adventure, these patches are the perfect solution. So go ahead, get creative, and let your brand shine with precision-cut soft PVC & rubber patches! A Strong Brand Identity on Employee Uniforms

- Company C: Creating Collectible Merchandise for Fan Engagement

Customization Options for Precision-Cut Soft PVC & Rubber Patches

When it comes to customizing your brand’s patches, precision-cut soft PVC and rubber patches offer a wide range of options. Firstly, you can choose from various shape and size variations. Whether you want a classic rectangle or a unique custom shape, these patches can be cut to your desired specifications.

Secondly, you have the freedom to select different attachment methods and backing options. From traditional sew-on patches to adhesive backings, magnetic attachments, or even hook-and-loop fasteners like Velcro, the choice is yours. This versatility ensures that your patches can be easily attached to a variety of surfaces.

Lastly, you can consider additional features to make your patches stand out. Think glow-in-the-dark elements for added visibility, reflective surfaces for increased safety, or even unique textures to give your patches a tactile appeal. These extra features add a touch of creativity and uniqueness to your brand’s patches.

Advantages of Precision-Cut Soft PVC & Rubber Patches over Traditional Embroidered Patches

While traditional embroidered patches have their charm, precision-cut soft PVC and rubber patches offer several advantages that make them a superior choice. First and foremost, these patches are known for their enhanced durability and weather resistance. Unlike embroidered patches that can fray or fade over time, PVC and rubber patches are built to withstand the elements, making them perfect for outdoor use.

Additionally, precision-cut soft PVC and rubber patches allow for greater design flexibility and detail. With embroidery, intricate details may be limited, but with these patches, you can achieve finer lines, gradients, and even small text with ease. This opens up a whole new world of design possibilities for your brand.

Lastly, consistency in color and texture is a notable advantage of PVC and rubber patches. Unlike embroidery, where thread colors can vary slightly, these patches offer a consistent color reproduction. Moreover, the texture of PVC and rubber adds a unique tactile element, making your patches visually and physically appealing.

Considerations for Choosing Precision-Cut Soft PVC & Rubber Patches for Your Brand

When deciding to incorporate precision-cut soft PVC and rubber patches into your brand strategy, there are a few key considerations to keep in mind. Firstly, assess your budget and quantity requirements. These patches can be more cost-effective for larger quantities, so evaluate your needs accordingly.

Secondly, consider your brand’s aesthetics and design objectives. Are you aiming for a sleek and modern look or a bold and vibrant design? Understanding your brand’s visual identity will help guide the customization options for your patches.

Lastly, think about your target audience and the intended use of the patches. Will they be given away as promotional items, used on employee uniforms, or sold as collectible merchandise? Tailoring your patches to suit your audience and purpose ensures they have maximum impact and relevance.

Case Studies: Successful Branding with Precision-Cut Soft PVC & Rubber Patches

Let’s take a look at a few real-life examples of how precision-cut soft PVC and rubber patches have helped brands elevate their visibility and identity.

- Company A: Boosting Brand Visibility at Trade Shows

Company A used custom-shaped PVC patches with glow-in-the-dark features on their trade show booth backdrops and giveaways. These eye-catching patches not only attracted attention in the crowded exhibition halls but also provided a lasting impression as they continued to glow after the lights went off.

- Company B: Establishing a Strong Brand Identity on Employee Uniforms

To create a cohesive and recognizable brand image, Company B incorporated precision-cut rubber patches with their logo onto employee uniforms. The patches added a professional touch while making their employees easily identifiable, reinforcing brand recognition in customer interactions.

- Company C: Creating Collectible Merchandise for Fan Engagement

Company C designed limited-edition PVC patches featuring their mascot. By releasing these collectible patches during special events or as part of fan engagement campaigns, they tapped into their loyal fan base’s desire for unique merchandise. The patches not only generated excitement but also served as mini-billboards for their brand when proudly displayed on backpacks, jackets, and hats.

In conclusion, precision-cut soft PVC and rubber patches offer a durable, versatile, and visually appealing solution for branding. With customization options, advantages over traditional patches, and considerations for choosing the right patches for your brand, you can create a lasting impact and reinforce your brand identity. So why settle for ordinary when you can have extraordinary patches that truly represent your brand?

In conclusion, precision-cut soft PVC and rubber patches offer a durable and versatile solution for enhancing your brand. With their enhanced durability, vibrant colors, and 3D texture, these patches provide long-lasting brand recognition and eye-catching design options. Their applications span various industries, from fashion to military, making them a versatile choice for any business. With the ability to customize shape, size, and additional features, these patches offer endless possibilities for brand personalization. By choosing precision-cut soft PVC and rubber patches, you can enjoy the advantages they have over traditional embroidered patches, including greater design flexibility and consistency in color and texture. So, why not take advantage of this innovative branding solution and elevate your brand identity to new heights? Start exploring the world of precision-cut soft PVC and rubber patches today.

Frequently Asked Questions (FAQ)

- Are precision-cut soft PVC and rubber patches weather-resistant?

Yes, precision-cut soft PVC and rubber patches are designed to withstand various weather conditions. They are highly durable and resistant to fading, cracking, and peeling, making them suitable for both indoor and outdoor use.

- Can I customize the shape and size of precision-cut soft PVC and rubber patches?

Absolutely! One of the key advantages of these patches is the ability to customize their shape and size according to your brand’s requirements. Whether you need a specific logo design or a unique shape, the patches can be tailored to meet your branding needs.

- What attachment methods and backing options are available for precision-cut soft PVC and rubber patches?

There are various attachment methods and backing options available for these patches. Common options include sew-on, iron-on, adhesive backing, and Velcro backing. You can choose the attachment method that best suits your intended use and application.

- How long does it take to manufacture precision-cut soft PVC and rubber patches?

The manufacturing process for these patches typically involves several steps, including design creation, mold making, injection molding, and finishing. The production time can vary depending on factors such as the complexity of the design, quantity required, and any additional customization features. It is best to consult with the manufacturer for a specific timeframe based on your project requirements.

PacificEmblem.com – the quiet FORCE in Custom Patches, Headwear and Accessories since 1985!

WHY NOT LET US MANUFACTURE YOUR CUSTOM PRODUCTS TODAY